Seamless stainless steel pipes are commonly used in our life. The application of seamless steel pipe is inseparable from the petroleum and chemical industries.

Differences

1. Processing point of view

From the processing point of view, hot rolling is hot processing, cold drawing is cold processing. Hot rolling is rolling at a temperature above the recrystallization temperature, and cold rolling is rolling at a temperature below the re crystallization temperature;

2. Appearance

From the appearance to distinguish cold-rolled seamless steel pipe surface bright, caliber size is smaller than hot-rolled seamless steel pipe. The hot-rolled seamless steel pipe has a larger caliber than the cold- rolled seamless steel pipe, and the surface has obvious scale or red rust.

3.Accuracy

In terms of accuracy: the accuracy of cold-rolled seamless steel pipe is higher than that of hot-rolled seamless steel tubes.

In terms of wall thickness, cold rolled seamless pipes are more uniform than hot rolled seamless tubes. It is sent to the automatic rolling mill for inherited rolling.

In order to obtain seamless steel pipes of smaller size and better quality, it is necessary to adopt cold rolling, cold drawing or a combination of the two.

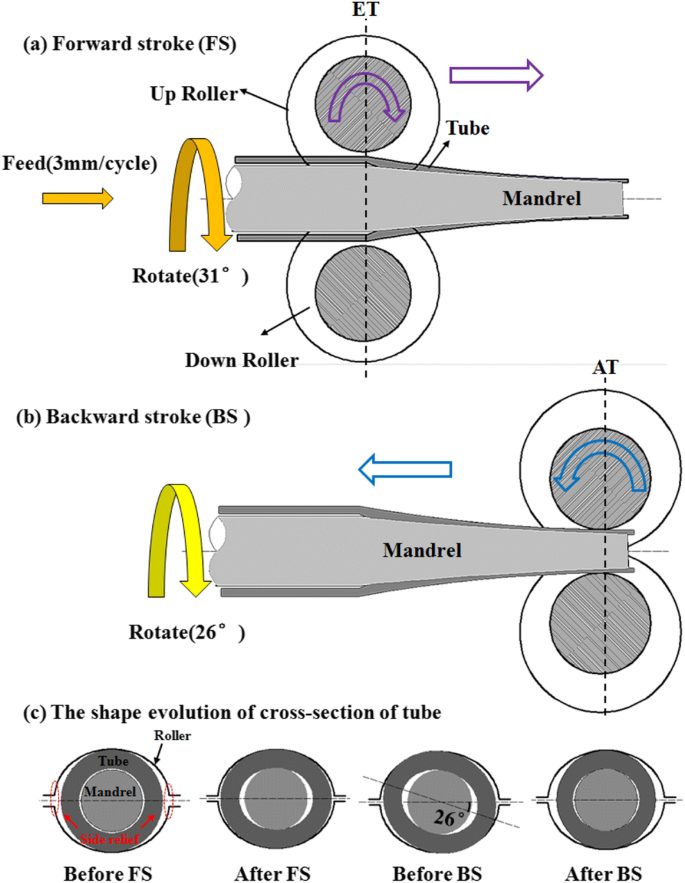

Cold rolling is usually carried out in a two-roll mill, and the steel pipe is rolled in between paired annular rollers (up roller and down roller) composed of a variable-section circular hole groove and a stationary tapered head. The groove caliber is formed along a circumference of each of paired rolls, and the groove caliber becomes narrower/smaller with the progress of rotation of rolls, repeat forward and backward strokes along the tapered mandrel pipe while being rotated by driven roll shafts, so that it rolled between the rollers and the mandrel to perform a diameter-reducing rolling of the mother pipe.

Again Sinton Tsingshan Brand seamless stainless steel pipe was manufactured by cold rolling, and cold drawing.